How two women pioneered lab automation at Color: ‘A milestone in lab development’

Sophie Xu, Color’s automation technical lead, watches over the automation process in the lab.

Color’s lab is committed to producing reliable and repeatable clinical results. Thousands of samples come through Color’s lab daily, and in order to ensure the samples are tracked, handled and stored in the best possible way, the lab relies heavily on automation. Sophie Xu, Color’s automation technical lead, and Sierra Fisher, a robotics engineer, collaborated to bring this innovative automation to life and continue to work together to further refine and update the lab’s processes as the science evolves. “We wanted to build custom automation that not only works seamlessly, but works best for our lab and our assay,” says Sierra.

Color’s lab automation framework began with stand-alone robots in 2015, when Color first launched. Before the launch of the current system, Color’s lab was composed of a series of standalone robots, each with a different interface. Every device ran a specific set of procedures, and the lab relied on scientists to transfer sample plates between devices. Over the next five years, Sophie, Sierra and their teams have written tens of thousands lines of code, built hardware, streamlined workflows and optimized chemistry in order to execute Color’s first integrated automation system, which now powers our high throughput lab.

Sophie Xu, automation technical lead; Sierra Fisher, robotics engineer

“We worked, and continue to work, as a lean team of four,” says Sophie, “So, supporting a production lab and developing new automation at the same time is a tough job.” Each team member brought a different set of knowledge to the table, from mechanical engineering, to software, to chemistry, to genetics and biology. The varied expertise combined with the focus on the same goal allowed for tag-teaming: When one team member is busy with a part of the project in their focus area, another member of the team can tend to more immediate problems, like troubleshooting for the production lab. “We frequently share our findings from different projects, which helps keep the whole team up to date.”

As they built the system and it continues to evolve, the team has consistently engaged with other teams across Color to understand how to make the system as usable as possible. In order to anticipate how operators will interact with the system, how it will react to errors or crashes, and how this new model will affect inventory of reagents, Sophie and Sierra’s team asked for feedback from the production team and technology transfer team. Sierra says, “the launching of this system involved not only our team, but other stakeholders across the company, which meant project management was key.”

“There was so much to learn,” says Sophie. “Everything was new to our lab.” To cover ground quickly, they each tackled different domains, with Sophie focused on the software integration side and Sierra learning the ins and outs of the new robots. The resulting new automation system includes several key components, like liquid handling robots, plate accessories and incubation devices. All of these components provide basic functionalities to process samples in the lab. Using these functionalities, the team was able to develop complex workflows and schedule them to maximize device usage and optimize efficiency.

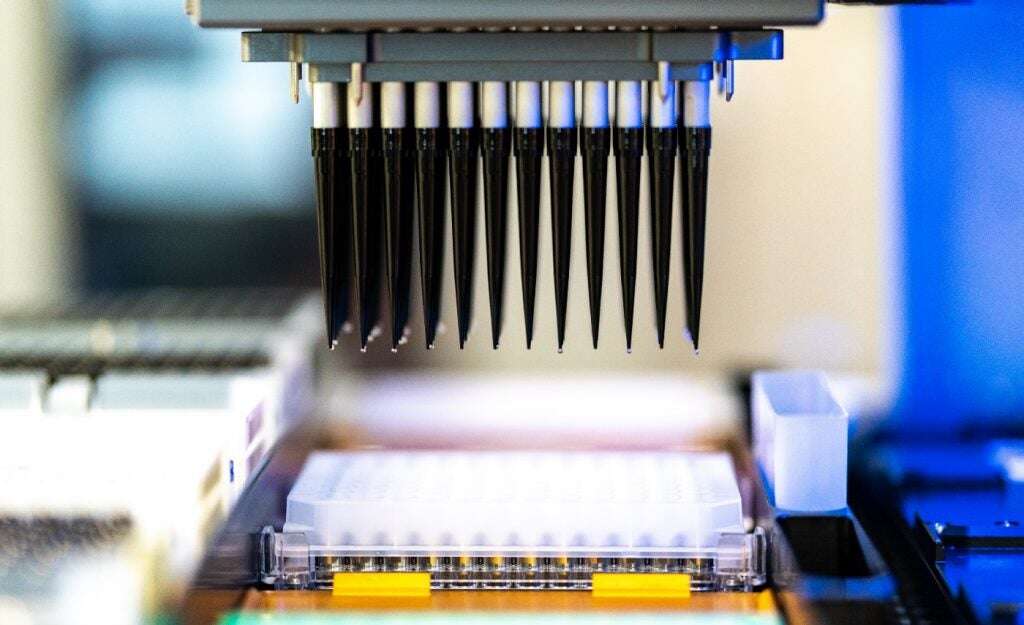

Pipettes in the Color lab.

The chemistry built by Sophie and Sierra’s teams is designed to be robust in order to buffer any variability from automation, and the automation, in turn, is optimized for carrying out precise chemical processes. The chemical process to prepare DNA for the sequencer is able to handle a range of concentration and quality of DNA, and DNA is amplified to more than is needed later in the process, so slight pipetting inaccuracies will not affect the final result. For automation, the team performs rigorous calibration for every robot and monitors their performance closely. They have also developed automated calibration techniques for more efficient, consistent and data-driven calibration.

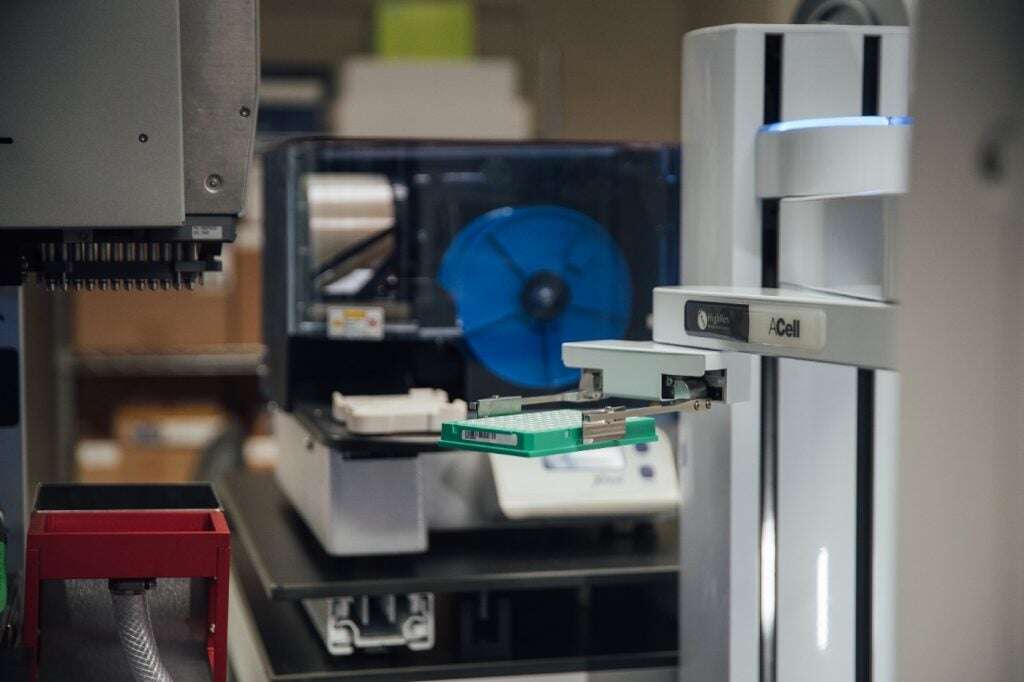

Building this kind of automation is no simple task, requiring the team to nurture relationships with new vendors, learn how to work with new software and hardware, design proprietary software — all to build an automation system that is easy to use and easy to monitor for the operators. This new integrated system has fewer human touchpoints and a uniform interface within our Lab Information Management System (LIMS) for all procedures. This means operators can start different processes through LIMS, load plates and consumables at designated loading racks, and the robotic arms will take care of the rest.

The robotic arm in Color’s lab frees up lab technicians to do more complex clinical work, instead of simply loading machines.

The LIMS interface is also designed to be simple to use for operators: the custom SOP (standard operating procedure) and runtime system monitoring is integrated into one flow on LIMS. This means the team has migrated process management and lab information tracking onto the same platform, which provides data that gives better insight into the performance of our lab. An operator can log in to LIMS and monitor the entire life cycle of a sample. The fully-automated system also includes multiple checkpoints throughout the process to make sure samples are on their right track, including:

– Plate barcodes (for sample tracking)

– Reagent lot ID (to check the expiration date and track inventory)

– Temperature (for process control)

Even with a small team, Sophie and Sierra have been able to achieve things in the lab process that previously haven’t been possible. For example, the lab can now have multiple plates full of samples in the pipeline concurrently at different steps of the process — this allows the lab to fully utilize the downtime of every instrument, as well as free up lab technicians to do more complex clinical work, instead of simply loading machines. Currently in the lab, the team has connected multiple stand-alone units with robotic arms and can now control them through Color’s custom Lab Information Management System (LIMS). “This is a milestone for our lab development, says Sophie. “A strong first step toward a fully automated lab that runs 24/7.”